Raise Your Equipment: Discover Costs Komatsu Undercarriage Parts Solutions

Raise Your Equipment: Discover Costs Komatsu Undercarriage Parts Solutions

Blog Article

Effective Solutions: Undercarriage Components for Heavy Machinery

When it concerns hefty machinery, the undercarriage is an essential part that usually establishes the general efficiency and efficiency of the equipment. Quality undercarriage parts play a significant duty in making certain the smooth operation and longevity of heavy machinery. From excavators to dozers, each tool depends heavily on its undercarriage to hold up against tough working conditions. However, damage are unavoidable, leading to possible concerns that can prevent performance and increase upkeep costs (komatsu undercarriage parts). In this discussion, we will certainly explore the importance of buying top-notch undercarriage components, usual wear challenges dealt with by heavy machinery drivers, the benefits of prompt replacements, standards for picking trustworthy providers, and crucial maintenance pointers to extend the life expectancy of undercarriage parts.

Relevance of Quality Undercarriage Components

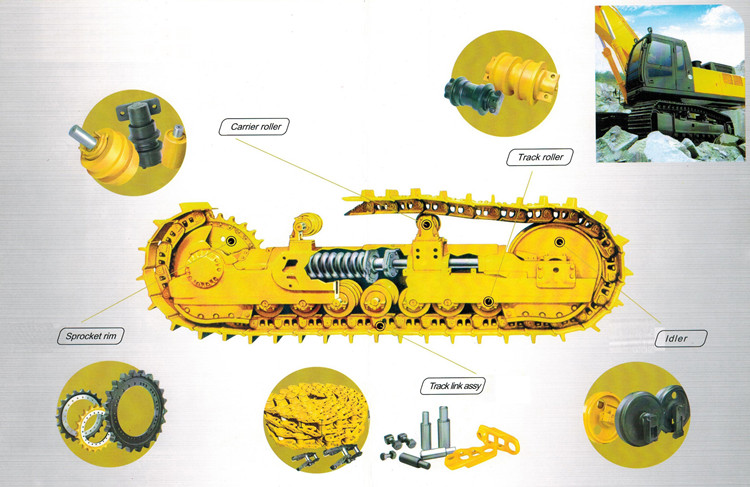

Quality undercarriage components are essential components in making sure the durability and performance of heavy machinery. The undercarriage of tools such as excavators, excavators, and track loaders plays a vital role in supporting the maker's weight, supplying security on numerous surfaces, and soaking up the influence of irregular surface areas. By spending in top notch undercarriage components, drivers can dramatically expand the life-span of their equipment and minimize the risk of unforeseen break downs.

One key benefit of using top quality undercarriage parts is the enhancement of general device performance. Durable tracks, gears, idlers, and rollers lower rubbing and guarantee smoother movement, ultimately leading to raised performance and effectiveness on job sites. Reputable undercarriage components decrease downtime for maintenance and fixings, enabling drivers to optimize their operational hours and task deadlines.

Usual Undercarriage Wear Issues

Advantages of Timely Substitute

One trick benefit of prompt undercarriage component substitute is boosted equipment uptime. By changing worn parts prior to they fall short, the danger of unforeseen malfunctions is reduced, minimizing downtime for repair work and maintenance. This aggressive strategy not just maintains the heavy equipment functional but also protects against potential damages to other components right here that can result from a failing undercarriage.

Additionally, changing undercarriage parts immediately can boost overall efficiency. Investing in timely undercarriage component substitute is a proactive technique that pays off in terms of enhanced performance and minimized functional costs.

Selecting the Right Undercarriage Vendor

Selecting the ideal undercarriage vendor is an important decision that significantly influences the performance and maintenance of hefty machinery. When picking a vendor for undercarriage parts, numerous variables must be thought about to make certain optimum performance and cost-effectiveness. A provider that supplies a broad selection of undercarriage components for various hefty machinery brand names and versions can be beneficial as it gives much more choices to satisfy certain requirements.

Additionally, reviewing the provider's consumer service and assistance is critical. A vendor that offers exceptional customer care, fast response times, and technological assistance can assist decrease downtime and ensure smooth operations. Price is also a substantial element to think about; nonetheless, it ought to not be the sole component. Stabilizing high quality, cost-effectiveness, and dependability is crucial when choosing the appropriate undercarriage supplier for heavy machinery. By very carefully reviewing these variables, you can pick a distributor that fulfills your needs and adds look at this now to the effective performance and maintenance of your heavy equipment.

Upkeep Tips for Extended Lifespan

To guarantee a prolonged life expectancy for heavy machinery undercarriage components, implementing a proactive upkeep routine is important. Regularly evaluating undercarriage components such as track chains, idlers, rollers, and sprockets for deterioration is crucial. Any indicators of damages or too much wear should be quickly dealt with to avoid additional damage and potential failures. Furthermore, maintaining the undercarriage clean from dust, debris, and harsh products can considerably extend its life expectancy. Greasing moving parts according to producer referrals helps reduce friction and prevent premature wear. Monitoring track stress and alignment is also vital to protect against uneven endure the undercarriage elements. Investing in quality undercarriage parts from credible providers is similarly vital for ensuring durability. By adhering to these upkeep ideas vigilantly, hefty equipment proprietors can enhance the performance and sturdiness of their undercarriage components, inevitably lowering downtime and operational expenses.

Conclusion

In verdict, high quality undercarriage parts are essential for the reliable operation of hefty machinery. Picking a trusted vendor and following appropriate maintenance methods are key to making sure the extended life-span of undercarriage components.

Extreme wear and tear on undercarriage parts of heavy machinery can lead to substantial operational difficulties and raised upkeep prices. Normal examinations, correct maintenance, and timely substitutes of worn undercarriage parts are important to mitigate these common wear troubles and make sure the optimal performance of heavy machinery.

A distributor that uses a wide choice of undercarriage parts for numerous heavy equipment brands and versions can be beneficial as it provides extra options to satisfy particular demands.

By complying with these maintenance ideas vigilantly, hefty machinery proprietors can maximize the performance and durability of their undercarriage components, ultimately lowering downtime and functional prices.

Report this page